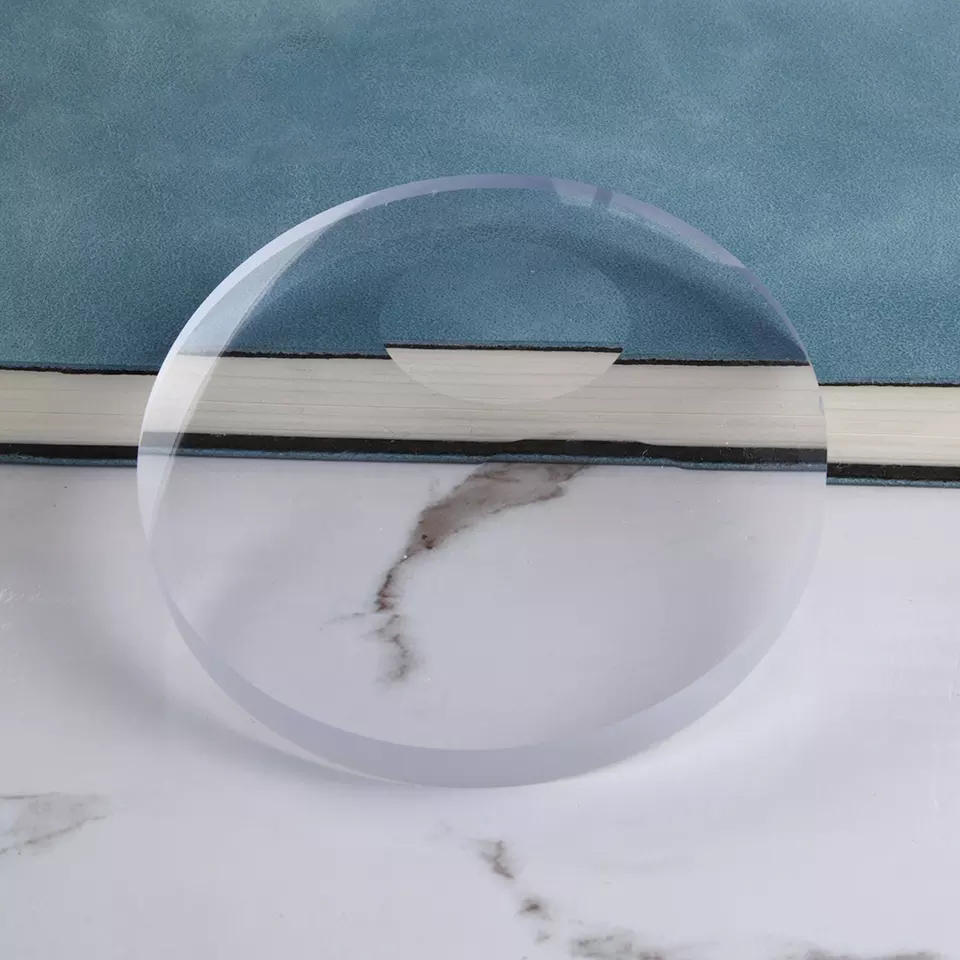

SETO 1.60 Semi-Finished Single Vision Lens

Specification

| 1.60 semi-finished optical lens | |

| Model: | 1.60 optical lens |

| Place of Origin: | Jiangsu, China |

| Brand: | SETO |

| Lenses Material: | Resin |

| Bending | 50B/200B/400B/600B/800B |

| Function | semi-finished |

| Lenses Color | Clear |

| Refractive Index: | 1.60 |

| Diameter: | 70/75 |

| Abbe Value: | 32 |

| Specific Gravity: | 1.26 |

| Transmittance: | >97% |

| Coating Choice: | UC/HC/HMC |

| Coating color | Green |

Product Features

1)The feature of CR39 lens

①The better among other index lenses in hardness and toughness , high impact resistance .

②The more easily tinted than other index lenses.

③The higher transmittance as compared with other index lenses .

④The higher ABBE value providing the most comfortable visual experience .

⑤The more reliable and consistent lens product physically and optically .

⑥The more popular in the middle level countries.

2)What's the importance of a good semi-finished lens to RX production?

①High qualified rate in power accuracy and stability

② High qualified rate in cosmetics quality

③High optical features

④ Good tinting effects and hard-coating/AR coating results

⑤Realize the maximum production capacity

⑥Punctual delivery

Not just superficial quality, semi-finished lenses are more focus on the internal quality, such as precise and stable parameters, especially for the popular freeform lens.

3)What is the difference between HC, HMC and SHC?

| Hard coating | AR coating/Hard multi coating | Super hydrophobic coating |

| makes the uncoated lens hard and increases the abrasion resistance | increases the transmittance of the lens and reduces surface reflections | makes the lens waterproof, antistatic, anti slip and oil resistance |

Certification

Our Factory