Stock Lens

-

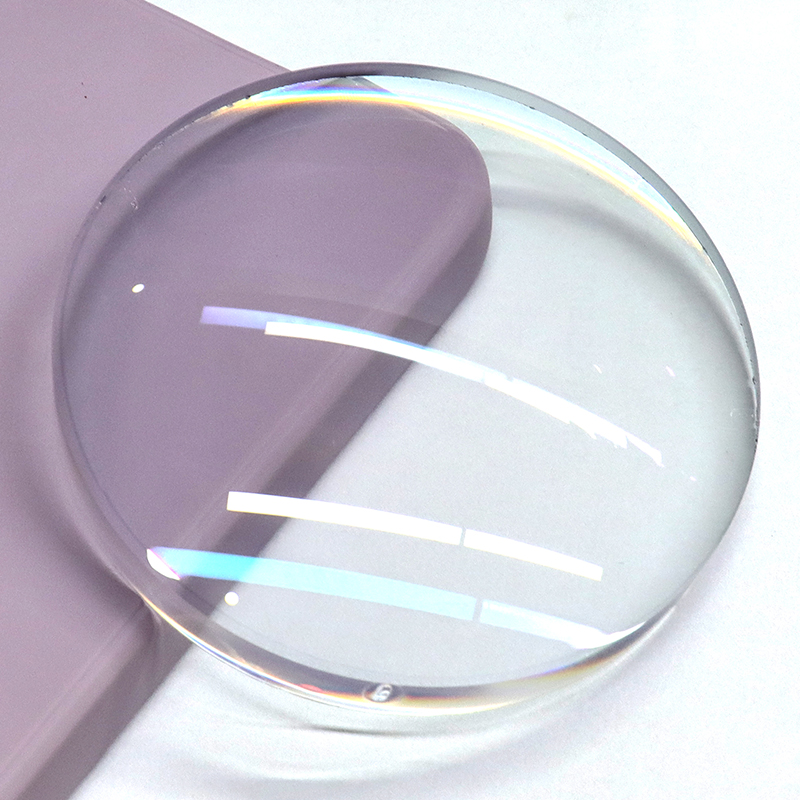

SETO 1.56 Semi-Finished Blue Block Single Vision Lens

Blue Cut Lens is to block and protect your eyes from high energy blue light exposure. Blue cut lens effectively blocks 100% UV and 40% of the blue light, reduces the incidence of retinopathy and provides improved visual performance and eye protection, allowing wearers to enjoy the added benefit of clearer and sharper vision, without altering or distorting color perception.

Tags: Blue blocker lenses, Anti-blue ray lenses, Blue cut glasses, 1.56 semi-finished lens

-

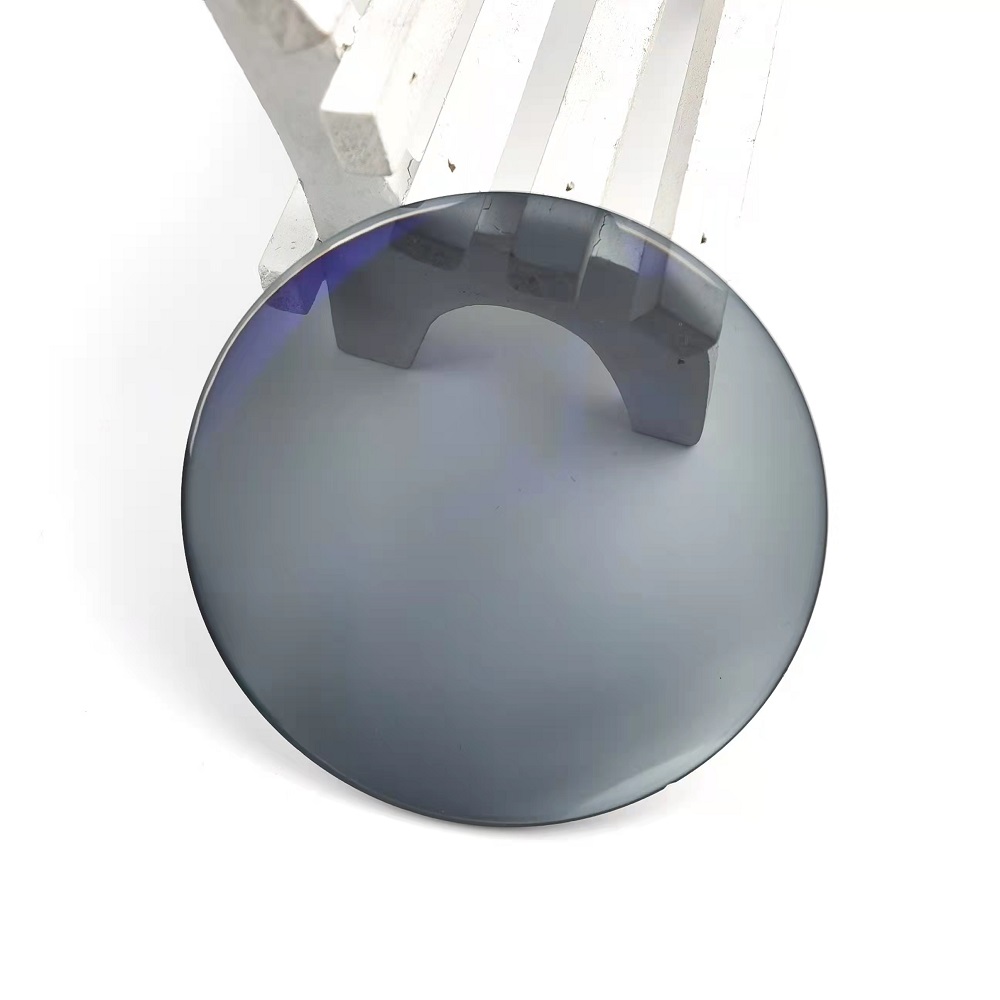

SETO 1.56 Semi-Finished Photochromic Lens

The molecules responsible for causing photochromic lenses to darken are activated by the sun’s ultraviolet radiation. Because UV rays penetrate clouds, photochromic lenses will darken on overcast days as well as sunny days.Photochromic lenses typically will not darken inside a vehicle because the windshield glass blocks most UV rays. Recent advancements in technology allow some photochromic lenses to activate with both UV and visible light, providing some darkening behind the windshield.

Semi-finished lens is the raw blank used to produce the most individualized RX lens according to thepatient’s prescription. Different prescription powers request for different semi-finished lens types or base curves.

Tags: 1.56 resin lens,1.56 semi-finished lens,1.56 photochromic lens

-

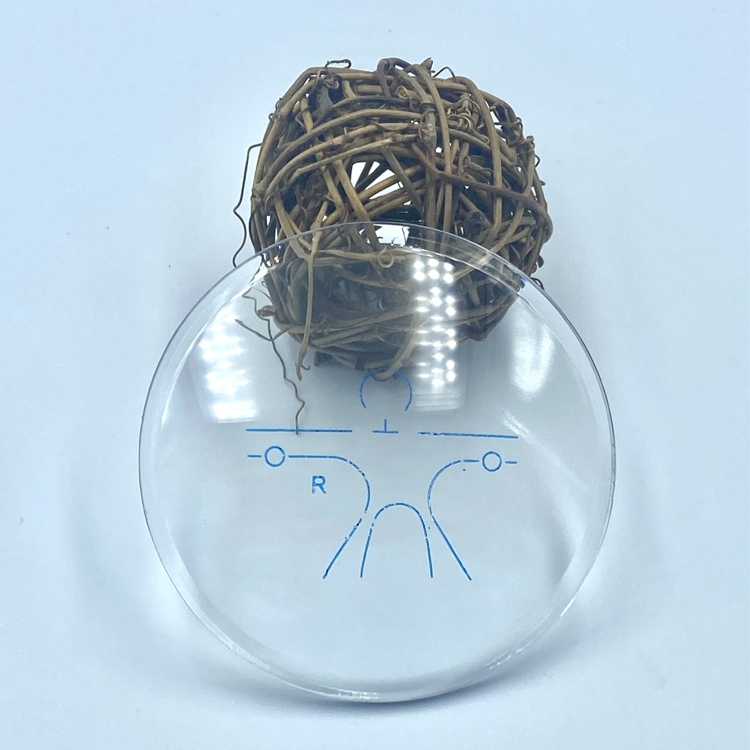

SETO 1.56 Semi-Finished Progressive Lens

Progressive lenses are line-free multifocals that have a seamless progression of added magnifying power for intermediate and near vision.The starting point for freeform production is a semi-finished lens, also known as a puck due to its resemblance to an ice hockey puck. These are produced in a casting process that is also used to manufacture stock lenses. The semi-finished lenses are produced in a casting process. Here, liquid monomers are first poured into moulds. Various substances are added to the monomers, e.g. initiators and UV absorbers. The initiator triggers a chemical reaction that leads to hardening or “curing” of the lens, while the UV absorber increases the UV absorption of the lenses and prevents yellowing.

Tags: 1.56 progessive lens,1.56 semi-finished lens

-

SETO 1.56 Semi-Finished Flat Top Bifocal Lens

Flat-top lenses were used to correct two different eye prescriptions. Bifocals were easy to spot – they had a line dividing the lens in two, with the upper half for distance vision, and the lower half for reading. The semi-finished lenses are produced in a casting process. Here, liquid monomers are first poured into moulds. Various substances are added to the monomers, e.g. initiators and UV absorbers. The initiator triggers a chemical reaction that leads to hardening or “curing” of the lens, while the UV absorber increases the UV absorption of the lenses and prevents yellowing.

Tags: 1.56 resin lens,1.56 semi-finished lens,1.56 flat-top lens

-

SETO 1.56 Semi-Finished Round Top Bifocal Lens

Semi-finished lenses need to have high qualified rate in power accurancy, stability and cosmetics quality. High optical features, good tinting effects and hard-coating/AR coating results, realizing the maximum production capacity are also available for a good semi-finished lens. Semi finished lenses can reprocessing to RX production, and as semi-finished lenses, not just superficial quality, they are more focus on the internal quality, such as precise and stable parameters, especially for the popular freeform lens.

Tags: 1.56 resin lens,1.56 semi-finished lens,1.56 round-top lens

-

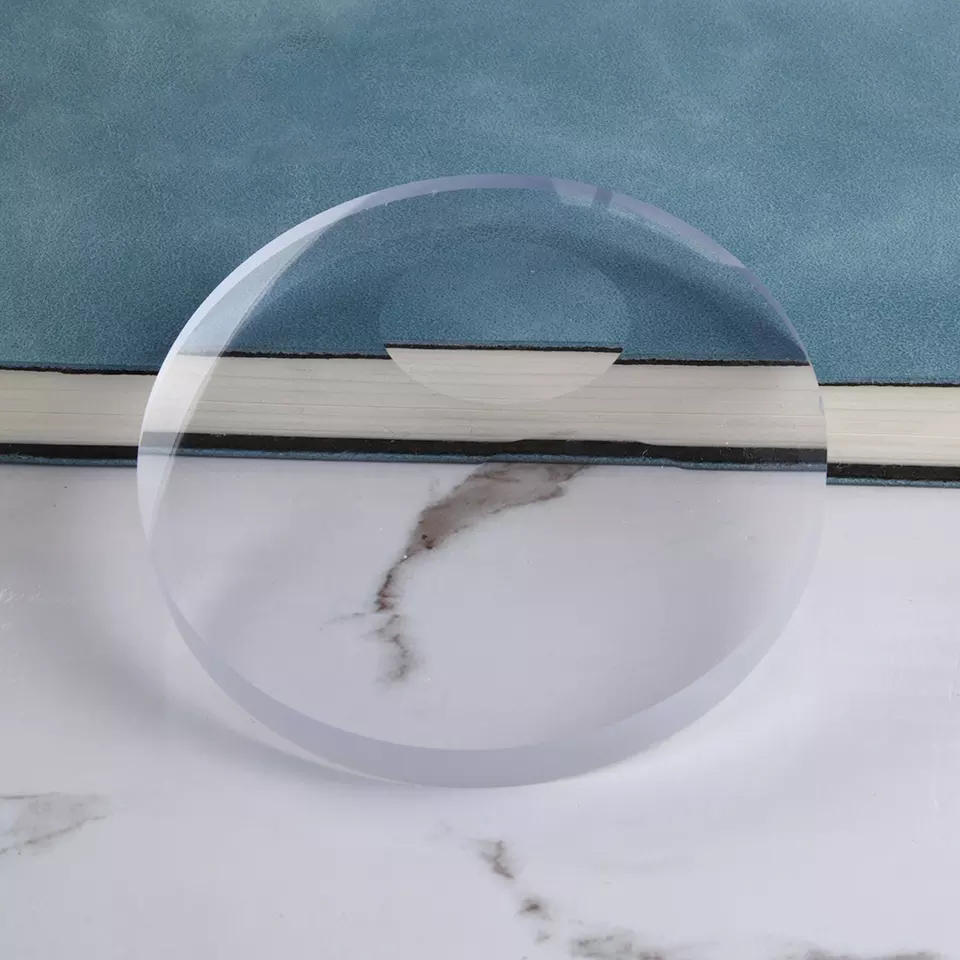

SETO 1.56 single vision Semi-finished Lens

The importance of a good semi-finished lens:

1. Semi-finished lenses need to have high qualified rate in power accurancy, stability and cosmetics quality.

2. High optical features, good tinting effects and hard-coating/AR coating results, realizing the maximum production capacity are also available for a good semi-finished lens.

3. Semi finished lenses can reprocessing to RX production, and as semi-finished lenses, not just superficial quality, they are more focus on the internal quality, such as precise and stable parameters, especially for the popular freeform lens.

Tags: 1.56 resin lens,1.56 semi-finished lens

-

SETO 1.59 single vision PC Lens

PC lenses are also called “space lenses”, “universe lenses”.It’s chemical name is polycarbonate which is a thermoplastic material (the raw material is solid, after heated and molded into the lens,it is also solid), so this kind of lenses product will be deformed when heated too much, not suitable for high humidity and heat occasions.

PC lenses have a strong toughness, are not broken (2cm can be used for bulletproof glass), so it is also known as safety lens. With a specific gravity of just 2 grams per cubic centimeter, it is the lightest material currently used for lenses. The weight is 37% lighter than ordinary resin lens, and the impact resistance is 12 times as much as ordinary resin lenses!Tags:1.59 PC lens,1.59 single vision PC lens

-

SETO 1.59 blue block PC Lens

The chemical name for PC lenses is polycarbonate, a thermoplastic material. PC lenses are also called “space lenses” and “ universe lenses”. PC lenses are tough,not easy to break and have strong eye impact resistance. Also known as safety lenses, they are the lightest material currently used for optical lenses, but they are expensive. Blue cut PC lenses can effectively block harmful blue rays and protect your eyes.

Tags: 1.59 PC lens,1.59 blue block lens,1.59 blue cut lens

-

SETO 1.59 Photochromic Polycarbonate Lens HMC/SHMC

The chemical name for PC lenses is polycarbonate, a thermoplastic material. PC lenses are also called “space lenses” and “ universe lenses”. PC lenses are tough,not easy to break and have strong eye impact resistance. Also known as safety lenses, they are the lightest material currently used for optical lenses, but they are expensive. Blue cut PC lenses can effectively block harmful blue rays and protect your eyes.

Tags: 1.59 PC lens,1.59 photochromic lens

-

SETO 1.59 Blue cut PC Progressive Lens HMC/SHMC

PC lens have high resistance to breakage which makes them ideal for all types of sports in which your eyes need physical protection. The Aogang 1.59 optical lens can be used for the all the outdoor activities.

Blue Cut Lenses is to block and protect your eyes from high energy blue light exposure. Blue cut lens effectively blocks 100% UV and 40% of the blue light, reduces the incidence of retinopathy and provides improved visual performance and eye protection, allowing wearers to enjoy the added benefit of clearer and sharper vision, without altering or distorting color perception.

Tags: bifocal lens,progressive lens,blue cut lens,1.56 blue block lens