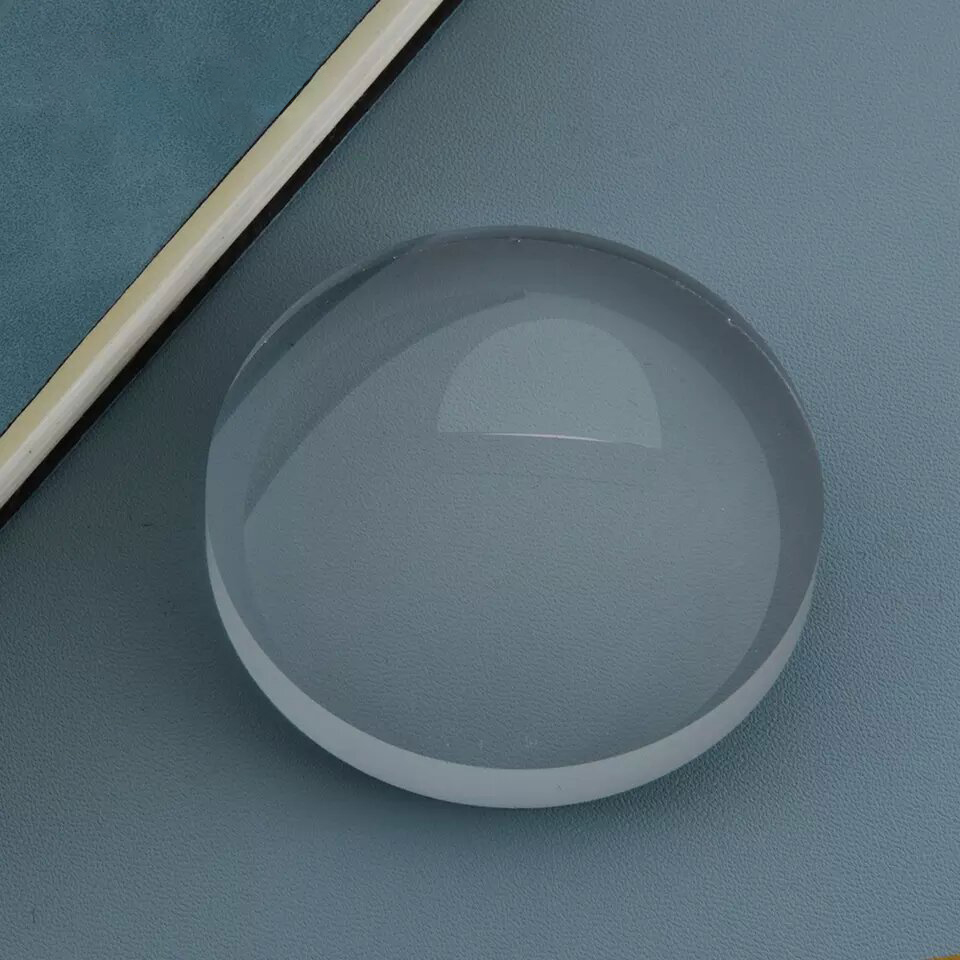

SETO 1.56 Semi-Finished Flat Top Bifocal Lens

Specification

| 1.56 flat-top semi-finished optical lens | |

| Model: | 1.56 optical lens |

| Place of Origin: | Jiangsu, China |

| Brand: | SETO |

| Lenses Material: | Resin |

| Bending | 200B/400B/600B/800B |

| Function | flat-top & semi-finished |

| Lenses Color | Clear |

| Refractive Index: | 1.56 |

| Diameter: | 70 |

| Abbe Value: | 34.7 |

| Specific Gravity: | 1.27 |

| Transmittance: | >97% |

| Coating Choice: | UC/HC/HMC |

| Coating color | Green |

Product Features

1. The advantages of the 1.56

①Lenses with a 1.56 index are considered the most cost effective lens on the market. They possess 100% UV protection and are 22% thinner than CR39 lenses.

②1.56 lenses can cut to fit the frames perfectly, and these lenses with knife edge finishing would suit those irregular frame sizes (small or large) and would make any pair of glasses look thinner than ordinary.

③1.56 single vision lenses have higher Abbe value, can offer wearers excellent wearing comfort.

2. The advantages of the bifocal lenses

①With a bifocal, distance and near are clear but the intermediate distance (between 2 and 6 feet) is blurred. Where intermediate is essential for a patient a trifocal or varifocal is required.

②Take the instance of a piano player. He can see distance and near, but the music notes he has to read are too far away. Hence, he has to have an intermediate section to see them.

③A lady who plays cards, can see the cards in her hand but cannot see the cards laid on the table.

3. What's the importance of a good semi-finished lens to RX production?

①High qualified rate in power accuracy and stability

② High qualified rate in cosmetics quality

③High optical features

④ Good tinting effects and hard-coating/AR coating results

⑤Realize the maximum production capacity

⑥Punctual delivery

Not just superficial quality, semi-finished lenses are more focus on the internal quality, such as precise and stable parameters, especially for the popular freeform lens.

4. What is the difference between HC, HMC and SHC?

| Hard coating | AR coating/Hard multi coating | Super hydrophobic coating |

| makes the uncoated lens hard and increases the abrasion resistance | increases the transmittance of the lens and reduces surface reflections | makes the lens waterproof, antistatic, anti slip and oil resistance |

Certification

Our Factory