SETO 1.56 Photochromic Blue Block Lens HMC/SHMC

Specification

| 1.56 photochromic blue block optical lens | |

| Model: | 1.56 optical lens |

| Place of Origin: | Jiangsu, China |

| Brand: | SETO |

| Lenses Material: | Resin |

| Lenses Color | Clear |

| Refractive Index: | 1.56 |

| Diameter: | 65/70 mm |

| Function | Photochromic&Blue Block |

| Abbe Value: | 39 |

| Specific Gravity: | 1.17 |

| Coating Choice: | SHMC |

| Coating color | Green |

| Power Range: | Sph:0.00 ~-8.00; +0.25 ~ +6.00; Cyl:0.00~ -4.00 |

Product Features

1) What is photochormice blue block lens?

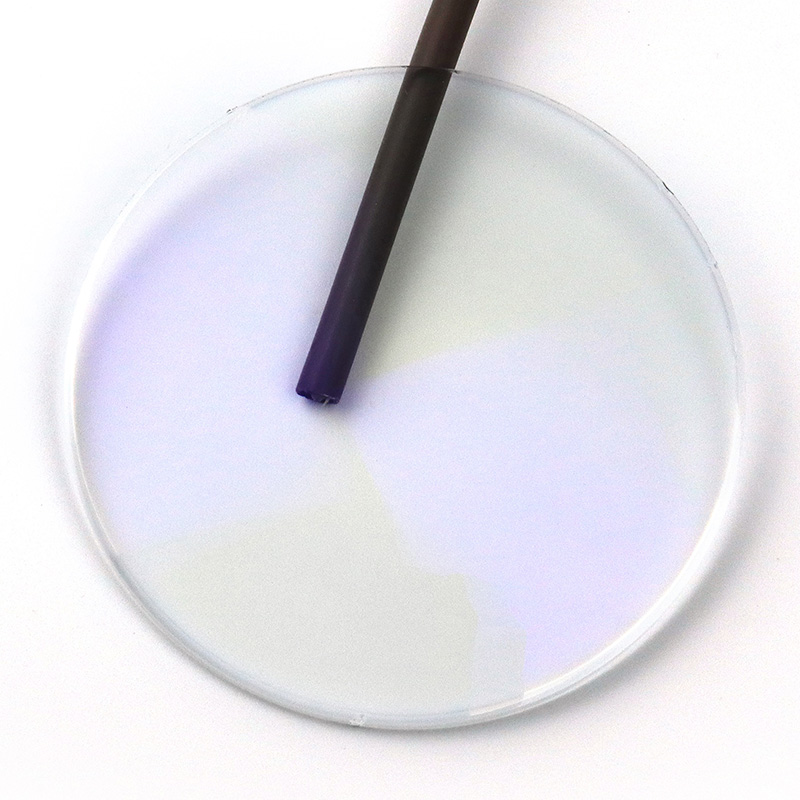

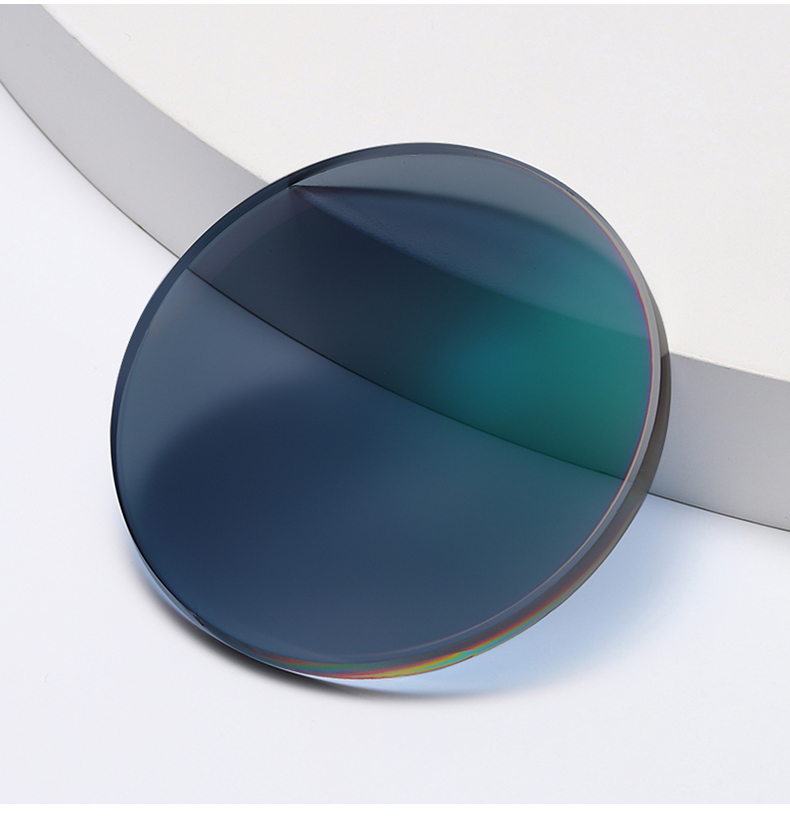

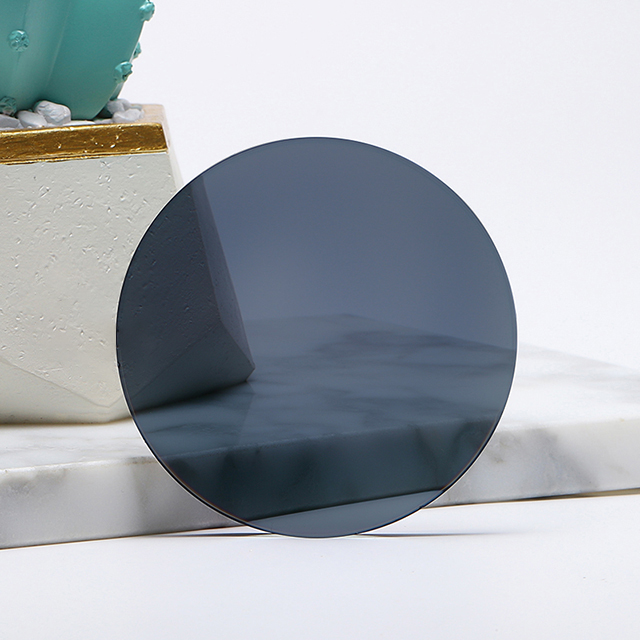

The photochromic blue cut lenses are optical lenses that darken automatically in response to the sun UV rays and then quickly return to be clear (or nearly clear) when indoors.At the same time, the photochromic blue cut lens can block harmful blue light and let the helpful blue ray to pass through.

Photochromic blue cut lenses offer the same amount of protection as sunglasses, without requiring you to purchase and carry around an extra set of eyewear. The following factors influence the light transmission and darkening speed: type of light, light intensity, exposure time and lens temperature.

2) How to make photochromic lenses?

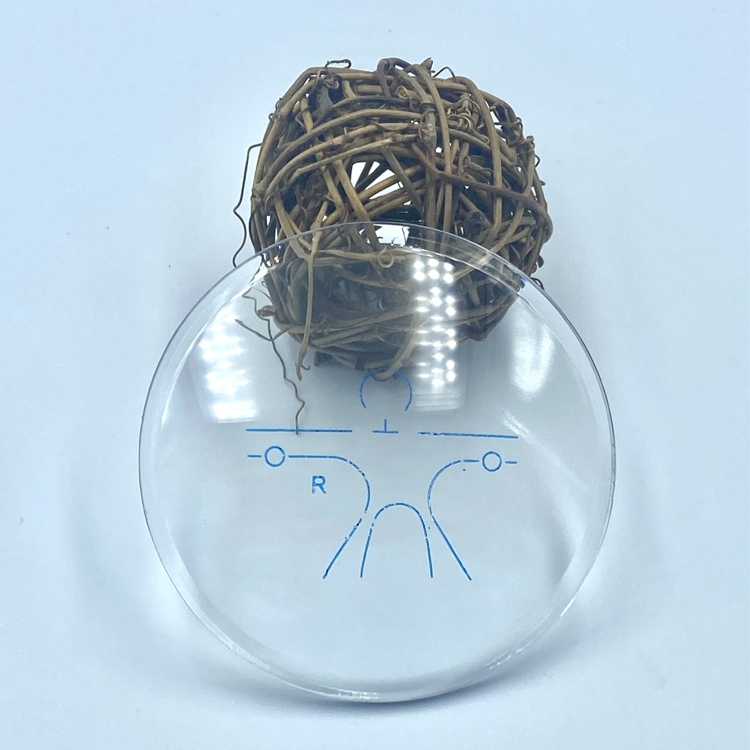

Photochromic lenses can be made by fusing a light-responsive chemical layer onto the surface of almost any plastic optical lens substrate. This is the technology used in Transitions lenses. However, they can also be made by incorporating photochromic properties directly into the lens substrate material. Glass lenses, and some plastic lenses, use this “in mass” technology. It is not as common.

3) What is the difference between HC, HMC and SHC?

| Hard coating | AR coating/Hard multi coating | Super hydrophobic coating |

| makes the uncoated lens hard and increases the abrasion resistance | increases the transmittance of the lens and reduces surface reflections | makes the lens waterproof, antistatic, anti slip and oil resistance |

Certification

Our Factory