SETO 1.56 single vision Semi-finished Lens

Specification

| 1.56 semi-finished optical lens | |

| Model: | 1.56 optical lens |

| Place of Origin: | Jiangsu, China |

| Brand: | SETO |

| Lenses Material: | Resin |

| Bending | 50B/200B/400B/600B/800B |

| Function | semi-finished |

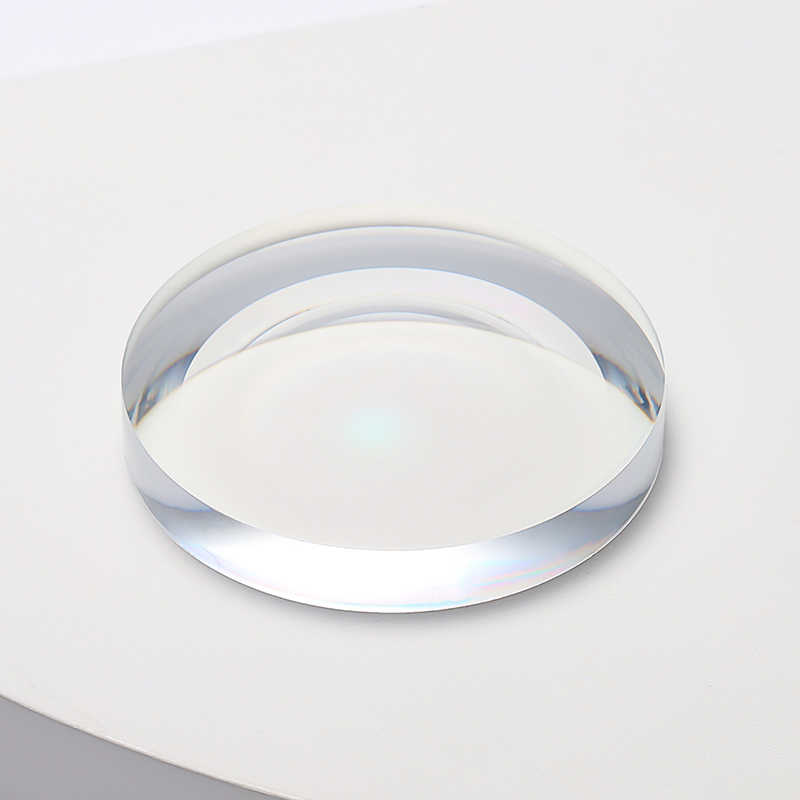

| Lenses Color | Clear |

| Refractive Index: | 1.56 |

| Diameter: | 70/65 |

| Abbe Value: | 34.7 |

| Specific Gravity: | 1.27 |

| Transmittance: | >97% |

| Coating Choice: | UC/HC/HMC |

| Coating color | Green |

Product Features

1.What is the semi finished lens?

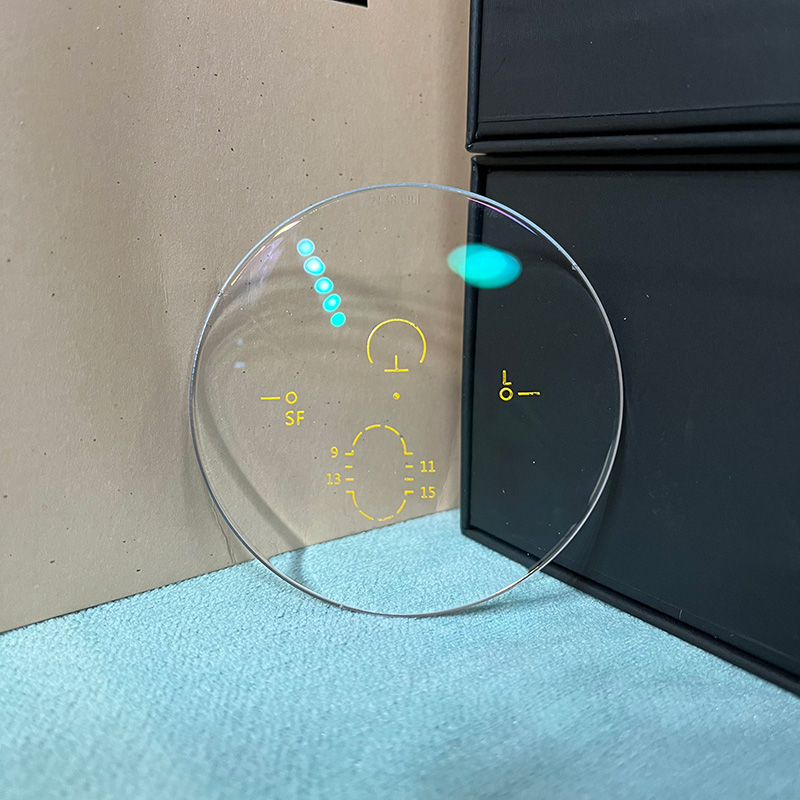

Lenses with different dioptric powers can be made from one semi-finished lens. The curvature of the front and back surfaces indicates whether the lens will have a plus or minus power.

Semi-finished lens is the raw blank used to produce the most individualized RX lens according to the patient's prescription. Different prescription powers request for different semi-finished lens types or base curves.

2. What's the importance of a good semi-finished lens to RX production?

①High qualified rate in power accuracy and stability

② High qualified rate in cosmetics quality

③High optical features

④ Good tinting effects and hard-coating/AR coating results

⑤Realize the maximum production capacity

⑥Punctual delivery

Not just superficial quality, semi-finished lenses are more focus on the internal quality, such as precise and stable parameters, especially for the popular freeform lens.

3.Index 1.56:

1.56 middle index lenses are one of the most popular lenses all over the world. This determines that Aogang 1.56 single vision lenses have the most outstanding optical features:

① Thickness: In the same diopters, 1.56 lenses will be thinner than CR39 1.499 lenses. As the increase in diopters , the difference will be bigger.

② Visual Effect: Compared with high index lenses, 1.56 lenses have higher ABBE value, can provide the more comfortable visual experience.

③Coating: The uncoated lenses are easily subjicted and exposed to scratches, hard coating lenses can effectly scratch resistance.

④Lenses with a 1.56 index are considered the most cost effective lens on the market. They possess 100% UV protection and are 22% thinner than CR-39 lenses. They are available with aspheric technology and are not recommended for a rimless drill mount due to its weak nature.

4. What is the difference between HC, HMC and SHC?

| Hard coating | AR coating/Hard multi coating | Super hydrophobic coating |

| makes the uncoated lens hard and increases the abrasion resistance | increases the transmittance of the lens and reduces surface reflections | makes the lens waterproof, antistatic, anti slip and oil resistance |

Certification

Our Factory