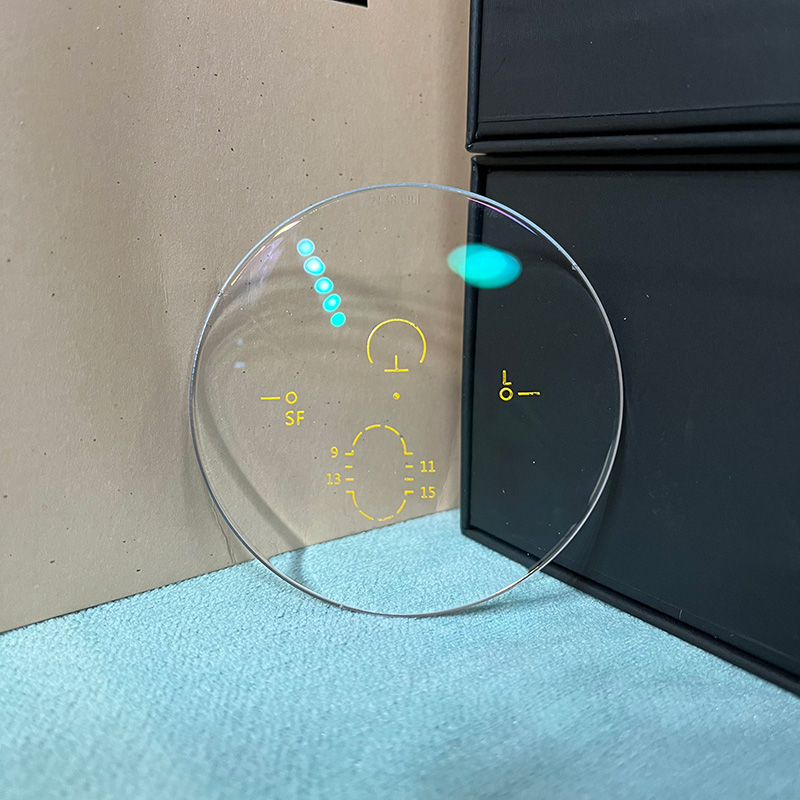

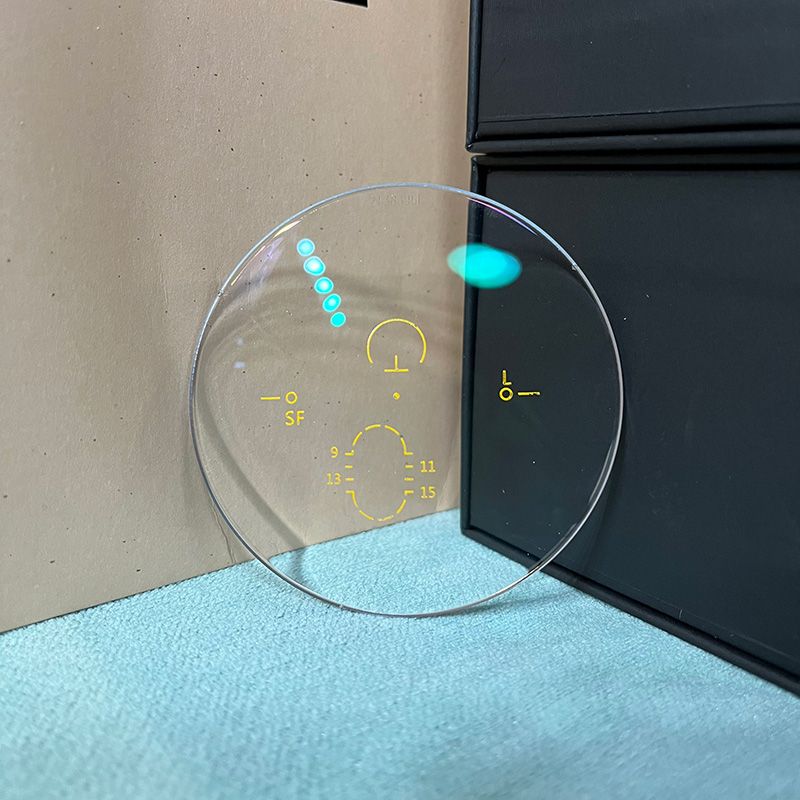

SETO 1.59 single vision PC Lens

Specification

| 1.59 single vision PC optical lens | |

| Model: | 1.59 PC lens |

| Place of Origin: | Jiangsu, China |

| Brand: | SETO |

| Lenses Material: | Polycarbonate |

| Lenses Color | Clear |

| Refractive Index: | 1.59 |

| Diameter: | 65/70 mm |

| Abbe Value: | 33 |

| Specific Gravity: | 1.20 |

| Transmittance: | >97% |

| Coating Choice: | HC/HMC/SHMC |

| Coating color | Green |

| Power Range: | Sph: 0.00 ~-8.00;+0.25~+6.00 CYL: 0~ -6.00 |

Product Features

1.What is Pc material?

PC: polycarbonate, belongs to thermoplastic material.This material is transparent, slightly yellow, not easy to change color, rigid and tough and it’s impact strength is particularly large, more than 10 times that that of CR 39, top-ranked of thermoplastic materials. Good stability to heat, thermal radiation, air and ozone. It can absorb all ultraviolet rays below 385nm, making it a safe lens. In addition to high heat resistance, oil resistance, grease and acid, low water absorption, a high degree of dimensional stability, it is a kind of environmental protection material which can be used countless times. Disadvantages are large stress, easy to crack, low miscibility with other resins, high friction coefficient, no self-lubrication.

2.The main features of PC lens:

①light weight

PC lenses have a specific gravity of 1.2, while CR-39 lenses has a specific gravity of 1.32, refractive index 1.56 has a specific gravity of 1.28, and glass has a specific gravity of 2.61. Obviously, among the same specifications and geometric size of the lens, PC lenses, due to the smallest proportion, further reduce the weight of the lenses.

②thin lens

PC refractive index is 1.591, CR-39 (ADC) refractive index is 1.499, Middle refractive index is 1.553. The higher the refractive index is, the thinner the lenses are, and vice versa. Compared with CR39 lenses and other resin lenses, PC myopia lenses edge are relatively thin.

③Excellent security

PC lens has extremely excellent impact resistance, known as the "king of plastic",can be widely used in the manufacture of aviation windows, bulletproof "glass", riot masks and shields. The impact strength of PC is up to 87/kg /cm2, which exceeds that of cast zinc and cast aluminum and is 12 times that of CR-39. The lenses made by PC are put on the cement ground to step on and not broken, and are the only "not broken" lenses. So far, PC lenses are second to none in terms of safety.

④absorption of ultraviolet rays

Modern medicine has confirmed that ultraviolet light is the main cause of cataracts in the eyes. Therefore, the requirements for ultraviolet light absorption of lenses are more and more clear. For general optical resin lenses, the material itself also has part of the performance of ultraviolet light absorption, but if you want to effectively prevent ultraviolet light through, you must add a certain amount of ultraviolet light absorbent while PC myopia lenses can 100% block ultraviolet light.

⑤good weather resistance

PC is one of the engineering plastics with excellent weather resistance. According to the experimental data of outdoor natural aging, the tensile strength, haze and etiolation indicators of PC did not change much after being placed outdoors for 3 years.

3. What is the difference between HC, HMC and SHC?

| Hard coating | AR coating/Hard multi coating | Super hydrophobic coating |

| makes the uncoated lens hard and increases the abrasion resistance | increases the transmittance of the lens and reduces surface reflections | makes the lens waterproof, antistatic, anti slip and oil resistance |

Certification

Our Factory